The term "guided surgery" is often used to suggest a minimally invasive and minimally traumatic surgical procedure; however, the advantages go far beyond these characteristics.

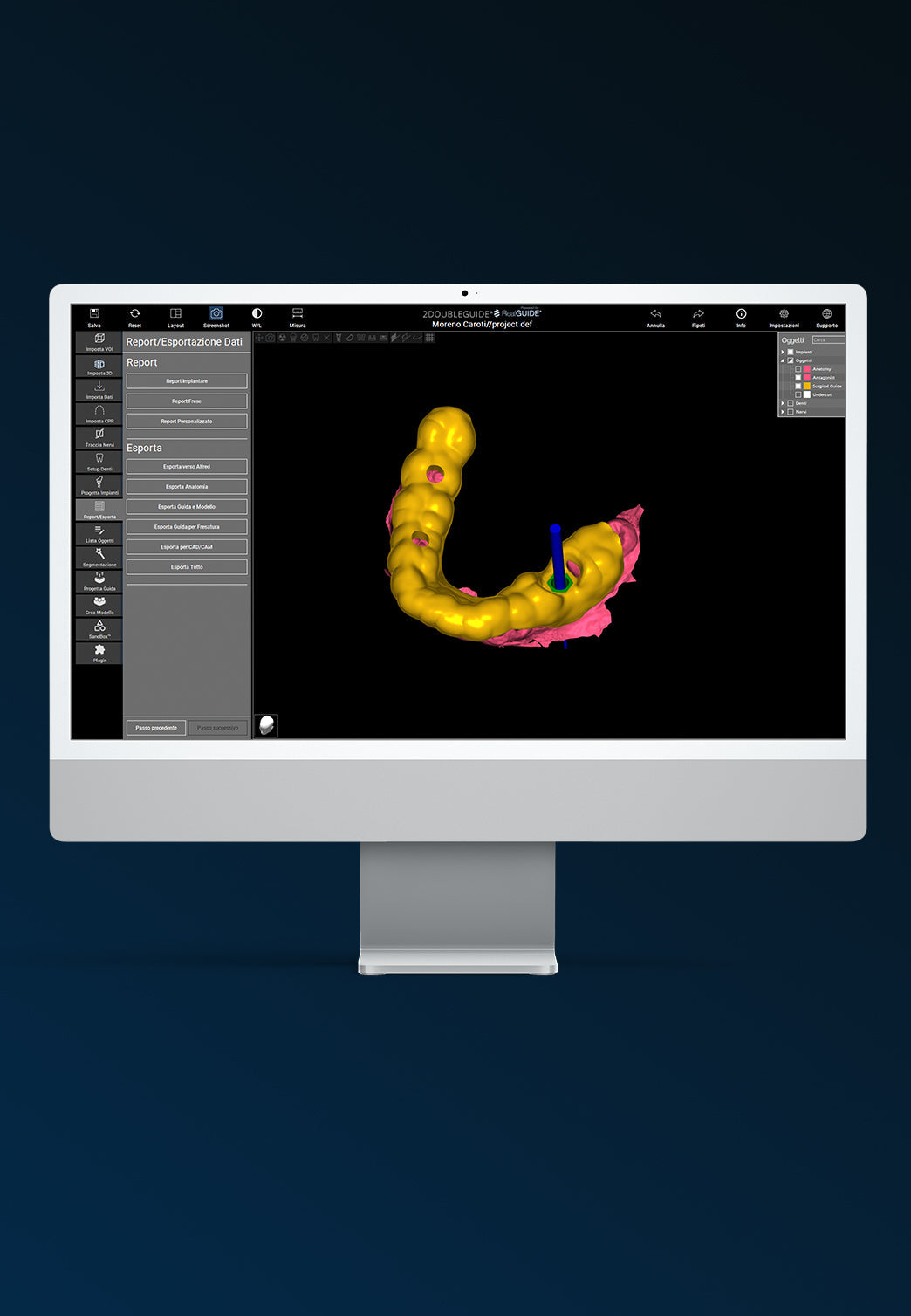

The true benefit of the "guided" technique lies in the precise planning and implementation of intraoperative devices that then transfer the digital project to the clinical phase. Using guided surgery therefore means being able to work with a precision and safety that can only be achieved with modern, high-quality technology.

The objective is conditioned by the detection of a precise and extensive impression of the affected arch (digital or scanned analogue) and by a tomographic examination with radiological landmarks that allow for perfect alignment between the two three-dimensional models.

Choosing this procedure certainly improves the quality of our therapeutic project.

Here are some aspects that are greatly improved in the process:

- we obtain a more precise evaluation of the area in which we plan to insert the implant with the anatomical structures at risk and its morphology;

- it becomes possible to perform a specific measurement of bone availability (height and width) with the possibility of pre-selecting the macro-morphology of the endosseous device;

- an initial assessment of bone quality can be performed by choosing the implant device that best suits the presumed bone class;

- it is possible to study the position of the implant and the prosthetic components consistent with the dental project, if a prosthetic rehabilitation project has been carried out on the model.

Given these premises, undertaking even the simplest implant surgery significantly increases safety for both the operators and the patient, because regardless of the clinician's training and experience, there is little room for the unexpected and improvisation.

The approach further increases its validity when dealing with “particular” insertions, in which the clinical and anatomical conditions can hardly be addressed based on superficial designs and subjective perceptions.

To better highlight the benefits, here are the case studies of two systems belonging to complex rehabilitation projects that well illustrate what is expressed.

Both projects were realized with BLACKBOX and B1ONE systems by IDI Evolution.

In a procedure such as the one depicted above, the indication followed by the clinician is: conserve the existing teeth with the consequent restoration of the missing ones with a fixed implant-supported prosthesis.

In this case, intra-sinus regenerative therapy is not recommended, and the operative choice remains the insertion of implants in the premolar and molar areas, particularly in the pterygoid abutment in area 28; furthermore, it was decided to sink the implant beyond the crestal plane to gain occlusal space for the prosthetic element.

Insertions in this anatomical area touch noble structures that, if affected, can create significant intra- and post-operative problems. The presence of these teeth contributes to the stabilization of the intraoral tray, reducing drilling speed and compression during insertion. These are other measures used to reduce surgical risk.

At the time of the post-operative radiological examination (CBCT low rad PLANMECA), following this procedure, the implant was inserted exactly as designed.

Another example is the following rehabilitation project of a patient (former ASO) who refuses the extraction of her retained canines, but still requires a fixed implant-supported rehabilitation.

Careful examination of the diagnostic material confirms the feasibility of the project, but what draws attention is the presence of the elements considered especially for the implant in position 14.

Also in this case, the residual teeth (which will be removed once osseointegration has occurred to allow for rehabilitation supported entirely by the implants) guarantee a precise position of the intra-operative template.

The control X-ray confirms the reproducibility of the implant project.

The result shown is the fruit of close collaboration with professionals who have been working for years to convert our surgical projects into real tools that simplify operations. IDI MAKERS by IDI Evolution , in Concorezzo, is the department that represents true Italian excellence in the sector and which, thanks to the industrialization of the process, allows clinicians to speed up component production times and reduce costs by up to 75%.

In a scenario where out of 1,600,000 implants inserted per year in Italy only 18% were inserted through guided surgery, IDI Evolution Since 2007, it has been pioneering the development of products and solutions designed to make surgery simpler and more accessible to all Italian clinicians.

IDI Evolution has revolutionized the dental industry, enabling 40% of its clients to work in a less invasive, more predictable and safer way, completing more than 35,000 cases for them to date.

Thanks to the doctor's study John the Baptist Mezzena , Carbonia, for the contribution.

Read the article on Odontoiatria33.

Share: